Challenges & Solutions

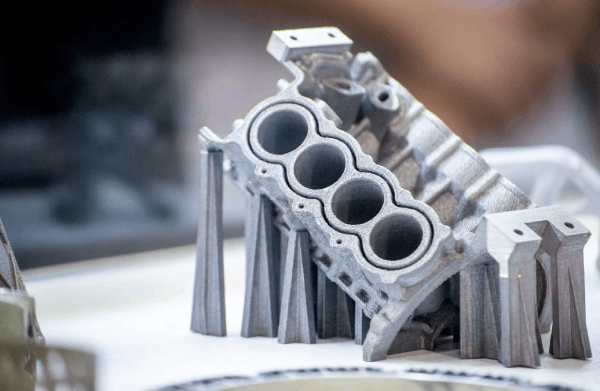

The production of parts for the mobility industry has usually been limited by constraints imposed by conventional manufacturing methods. Additive manufacturing (AM) is a rule-breaking industry disruptor. The basic principle is that an AM product lives as a set of digital instructions. A 3D printer then "prints" these parts one layer at a time.

Additive manufacturing gives design freedom — no more molds — and the ability to use a wider variety of materials. The process can generate complex 3D parts in their entirety and thereby reduce points of weakness. With print-on-demand services and minimal use of lightweight materials, additive manufacturing is the way of the future – especially in sustainable mobility operations.

The Challenge

The mobility industry is bullish on additive manufacturing as a way to realize multiple goals at the same time: printing on demand to use raw materials only as needed, accommodate supply chain challenges, and improving sustainability by seamlessly manufacturing complex parts with lightweight materials.

The advantages notwithstanding, the process does have significant obstacles to overcome. For one thing, while AM dates back several decades, much of the technology still feels nascent. Mobility enterprises have mostly kept their intellectual property sealed with the result that many successes in additive manufacturing have come in dribs and drabs.

Because of the hesitancy to share process information, there is a dearth of reliable data on which to base a wider range of standards than we have now. It’s a cycle that keeps perpetuating. A lack of collaboration in the field makes additive manufacturing suspect. Enterprises are hesitant to invest in the field because they might be unsure of part performance and reliability in mobility.

Because of the sporadic nature of successes, enterprises continue to question the efficacy of the process. Additive manufacturing is a fundamental design reboot so the industry needs to undergo an attendant mind shift.

One of the biggest challenges we face is the nurturing of a talented workforce that understands the rules of additive manufacturing and that can help the mobility industry embrace and profit from the process.

The Fullsight Solution

Leaning on our decades of experience in the mobility industry, Fullsight can bring people, processes and technologies together to accelerate momentum in the additive manufacturing space. We understand how to facilitate connections across government and industry and are ready to do so in the AM ecosystem.

Understanding that we need a strong shared ground of established practices for additive to scale as needed, Fullsight can convene leaders and experts and develop a forum where all stakeholders share data non-competitively. We stand ready to act as a data management resource not only through our established banks of publications and documentation but by exploring new ways of integrating digital information for a new data-driven age.

Additive manufacturing might be a radical approach for the creation of goods but its end result, products that need to be used in the real mobility world, are often not. We still need standards for material specifications and processes. We still need organizations to be certified and professionals to be audited. We do however need to reconfigure these old processes to accommodate new implementations. Fullsight has the expertise and a deep bench of talent to do just that.

Fullsight has seen that the onesies and twosies approach to additive manufacturing has constrained the pace of development and fostered an unwarranted era of mistrust. Our neutral voice and commitment to pave an unbiased platform on which the industry can stand, has won us abiding trust in the mobility industry. We can now use that trust to facilitate certification, production, and maturation for additive manufacturing.

Expect Fullsight to keep an eye on emerging insights in AM and to pave the way for its continued successes in mobility.